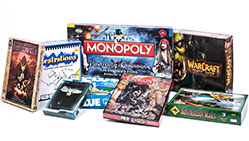

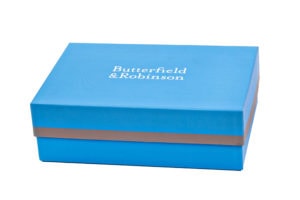

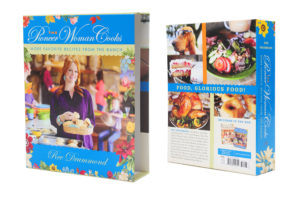

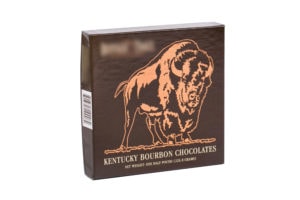

2 Pc. Box – Base and Lid

Most common rigid box construction. Highest consumer and shelf appeal of all box packaging. Other box packaging tries to imitate the 2 pc. rigid set-up box but there is no replacement. Option to add pre-production or post-production die cuts on top and sides of the lid; with or without a transparent window.